The EVs of the future those arriving after 2025 could shift to sodium ion or lithium sulfur battery cells that could be up to two-thirds cheaper than today’s lithium ion cells.

Table Of Content

American taxpayers may give themselves a collective bear hug because the gas-powered automobile era is coming to a gradual and steady end. Millions of dollars in research and development funding from the United States Department of Energy have led to innovations that allow electric vehicle batteries to charge more quickly, last longer, and be used in a safer environment. Scientists at the U.S. Department of Energy have recently made progress in finding a key ingredient that could make lithium-ion EV batteries hold four times as much energy.

Your Tax Dollars at Work: Better EV Batteries

The new development is the result of a huge public-private energy storage program called Battery500 Consortium, which was started during the Obama administration and is run by the Energy Department’s Pacific Northwest National Laboratory.

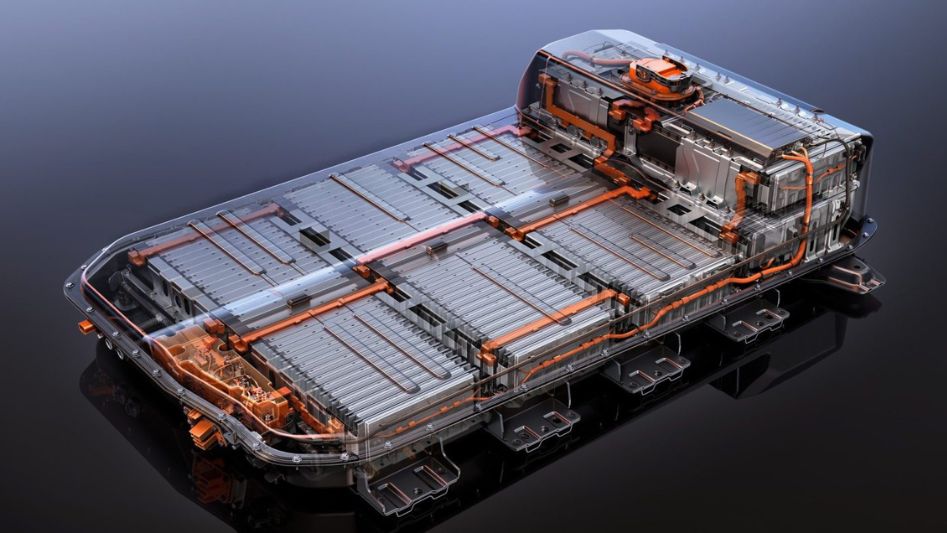

As of 2012, the price of EV batteries had risen to over $500 per kilowatt-hour, thus the consortium set out in 2016 with a $50 million, five-year aim to enhance performance and lower cost. Lithium-metal technology, in which lithium is employed instead of the graphite often used in EV battery engineering, is the major emphasis. Lithium-metal batteries, like those used in electric vehicles, use a solid electrolyte rather than the more common liquid one.

The goal of the Battery500 Consortium is to achieve 1,000 recharges in electric cars while tripling the specific energy (to 500 WH/kg) compared to current battery technology. The White House explains that this will lead to cheaper electric vehicles with smaller, lighter battery packs (below $100 per kWh).

Although lithium anodes may provide more density, durability remains a problem. The consortium’s 600-cycle demonstration in 2021 was a major step forward but still fell far short of the ultimate target.

The first group of researchers included PNNL, the Brookhaven and Idaho national labs, the SLAC National Accelerator Laboratory, and universities in New York, California, and Texas. IBM and Tesla, which was called Tesla Motors at the time, were also involved.

The Search for a Better EV Battery Continues

And with that, Phase I is complete. The Battery500 collaboration was renewed for a further five years in December at a cost of $15 million per year. Phase I’s Energy Department laboratories and university partners will continue on into Phase 2, with the exception of IBM and Tesla, which have been replaced by General Motors (more on that in a second). More schools from Texas, Pennsylvania, and Maryland have joined as well.

The next generation of batteries will lead to a North American battery manufacturing and electric car sector, according to M. Stanley Whittingham, a renowned professor of chemistry at Binghamton University in New York State. “Phase 2 will enable us to build on the achievements of the prior five years and give the leadership essential for building the next generation of batteries,” he added. In 2019, Professor Whittingham won the Nobel Prize for his contributions to the development of lithium-ion batteries.

Note that Whittingham shared the award with Professor John Goodenough of the University of Texas at Austin, another member of the consortium and a recognized expert in the subject of energy storage.

The Latest EV Battery Breakthrough

Phase II of the Battery500 Consortium’s efforts is focused on bringing the price of lithium-metal EV batteries down to below $100 per kilowatt-hour while increasing their energy density to up to 500 Wh/kg.

Recent findings have come from a team researching the interphase, led by researchers at Brookhaven National Laboratory. Every time the battery is charged, a “squishy” layer called the interphase forms between the anode and the electrolyte. It’s been called the “secret to stabilizing lithium-metal batteries.”

That complete battery’s cyclability is affected by the interphase. “It’s a really significant but elusive system,” said Enyuan Hu, the team’s leader and a chemist at Brookhaven. This tiny, delicate sample contains both crystalline and amorphous phases, making it vulnerable to damage from a wide variety of procedures.

Even though cryo-electron microscopy and other advanced technologies have been used in previous research to probe the interphase, many questions remain unanswered. The Brookhaven group has been using the National Synchrotron Light Source II to flood them with very strong x-rays. Even though the rays are powerful, they are safe enough to allow a thorough examination of the material in both stages.

Three Big Breakthroughs for Better EV Batteries

The result was not one but three breakthroughs

According to the latest findings, lithium hydride in the interphase is most likely produced from lithium hydroxide at the anode. The group believes the finding will lead to enhanced interphase functionality.

Another discovery made by the group was that significant amounts of lithium fluoride may be formed in the low-concentration electrolytes. This contradicts the findings of other studies that suggested intensive focus was required. If the findings of the current study hold up, the quantity of costly salts required to attain a high concentration in the next generation of batteries may be reduced.

The third big step forward was a better understanding of what happens during charge-discharge cycles. This made it possible to use up lithium hydroxide more quickly.

The US Army Wants Better EV Batteries

There is still a long way to go, but the United States Army is helping to make progress more quickly. GM might have shown up because of its work on the Battery500 Consortium initiative. With funding from the US Army Ground Vehicle System Center, the Consortium issued a request for solid-state “seedling” ideas in September (GVSC).

In the RFP, improvements are sought in six categories, one of which is the thickness of the solid-state electrolyte (“it has to be thin,” they add). The suppression of dendritic outgrowth is a secondary goal.

Even though progress on the Army’s interest in electric vehicles has been gradual over the past several years, things have been heating up in the last few months. Oshkosh, a defense contractor, is among those pushing for a conversion to electric driving. Earlier this year, GM’s GM Defense division said that it would lend the Army one of its all-electric GMC Hummers for testing and evaluation purposes.

“GM Defense will leverage the GMC HUMMER EV, incorporating GM’s Ultium Platform, to answer the U.S. Army’s demand for a light to heavy duty battery electric vehicle to enable decreased dependence on fossil fuels both in the operational and garrison contexts,” GM Defense said, adding that the vehicle “has 1,000 horsepower, 11,500 lb-ft of wheel torque, and is capable of full 350 kilowatt/800 volt DC rapid charging, allowing up to almost

Stay tuned for more information as the Army spends money on research into solid-state energy storage. The goal is to make portable batteries for troops that are more powerful and lighter.

Conclusion

In terms of its function, the battery has always been an afterthought, a bottleneck, and a parasite. Today, it is dissolving before our very eyes, assimilating into the wires and circuits that make up our modern world. The days of separate energy storage units will soon be gone, joining the ranks of the dial-up modem and the portable CD player as relics of the past. It’s the stuff of magic: you see it now, but you won’t be able to any longer.

FAQs

What is the most promising EV battery technology?

To boost energy density by 20–40% and charging speed by 2–4 times, Sila Nanotechnologies is replacing the graphite anode that makes up most of the bulk and around 15% of the weight of modern lithium-ion batteries with a type of silicon.

Who is making solid-state EV batteries?

Battery producer Solid Power, founded in 2011, promises their SSBs will be safer, give greater energy, and cost less than lithium-ion batteries. As a result, many automobile manufacturers, including BMW and Ford, have invested in the company.

What is the new battery technology for electric cars?

The novel battery design has ultrathin nickel foil between the anode and cathode, in addition to the anode, electrolyte, and cathode. The nickel foil acts as a trigger, which lets the battery self-regulate its temperature and reactivity. This means that almost any EV battery can be charged in just 10 minutes.

You May Also Like

- SOLAR BOTANIC TREES: ARE THEY THE FUTURE OF EVS CHARGING STATIONS?

- NEW LITHIUM MINE TO BE POWERED BY SOLAR, WIND & BATTERIES

- CAN THIS METAL DO BETTER THAN LITHIUM BATTERIES?

- HERE ARE THE BATTERIES THAT COULD POWER THE FUTURE

- RENEWABLE ENERGY: THE FACTS OF THIS GREEN REVOLUTION